The Heat Is On

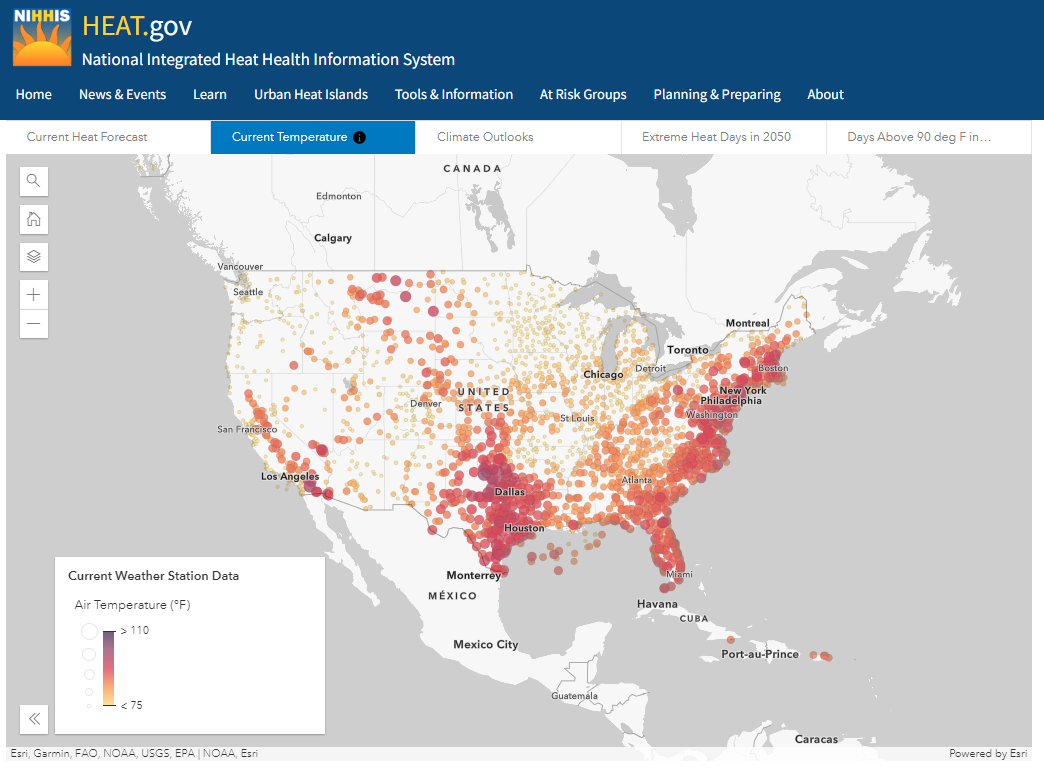

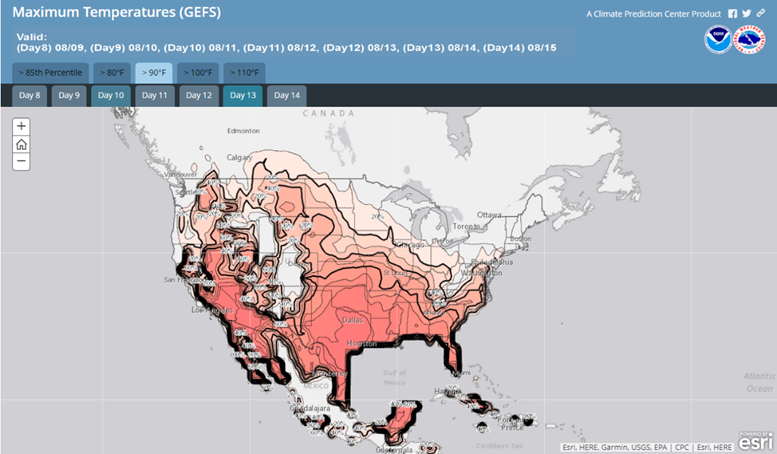

Last week, the Biden administration launched a website that coordinates information on extreme heat. The site provides tools to help employers prevent heat-related illnesses in employees. In addition, the website includes information on who is most at risk of extreme heat.

The release of this website comes on the heels of the Department of Labor’s (DOL) ongoing efforts to prepare a heat standard for employers. In October 2021, the Biden administration published an Advanced Notice of Proposed Rulemaking (ANPR), asking the public what a heat standard should include. If finalized, the heat standard rule would provide more oversight to the Occupational Health and Safety Administration (OSHA) on employers. In simple terms, it would allow OSHA to cite employers for violations of the standard. Employers have raised concerns about a heat standard at the federal level, as variations in weather across the country can be extreme, and heat standards should be state or regionally specific.

Under normal circumstances, a final rule would take 2-3 years to complete. Last week, however, some members of Congress weighed in and moved legislation out of a House Committee that would direct the DOL to fast-track the development of a heat illness standard within one year of enactment of the legislation. In the interim, between websites, and proposed rules and legislation, OSHA is currently conducting more worksite audits under the National Emphasis Program for Outdoor and Indoor Heat-Related Hazards. This program allows OSHA to inspect and recommend to employers how to improve worker conditions.

Forest products industry employees often work in outdoor and indoor environments under extreme heat conditions. These environments can increase the chance of heat-related illnesses. From loggers to papermills to sawmills, employees face varying degrees of working conditions that increase the likelihood of heat-related illnesses. Employers in this sector must have up-to-date heat prevention safety plans, and employees must be aware of the safety plan protocols through training.

For employers who are updating their plans or want to ensure their existing plan covers all the critical elements, the International SOS Group identifies ten key elements for a workplace heat safety program:

1. Monitoring Heat Hazards

Managers must be trained to monitor the conditions in the workplace and respond to excessive heat. Many factors have a role in creating an occupational heat stress risk to employees, including:

- Environmental conditions (e.g., temperature, humidity, sunlight, and airspeed), especially over sequential days.

- Worksite heat sources (e.g., heavy equipment, hot tar, ovens, furnaces).

- Level of physical activity/strenuous workloads.

- Heavy or synthetic clothing or personal protective equipment (PPE).

- Individual risk factors and high-risk conditions.

With the help of an occupational health advisor, consider installation of wet bulb globe temperature (WBGT) monitoring devices—the gold standard for precisely measuring heat stress. WBGT measures heat stress in direct sunlight, taking into account temperature, humidity, wind speed, sun angle, and cloud cover. If WBGT is unavailable, continuously monitor the local heat index and plan heat safety precautions accordingly.

2. Medical Monitoring of Employees Working in Heat

Medical monitoring for all employees exposed to heat stress should include pre-placement and periodic medical evaluations to assess personal risk factors for heat illness. Continuous medical monitoring may be recommended for employees working in conditions of high levels of heat stress (e.g., core temperature, hydration, pulse, and/or blood pressure). An occupational health advisor should be engaged to develop a medical monitoring program specific to the worksite.

3. Emergency Action Plan

Establish a worksite emergency action plan that outlines how to recognize the signs of heat illness, administer first aid, provide immediate cooling measures and contact emergency medical services. Ensure all employees know the emergency action plan and conduct regular refresher training, especially during heat advisories.

4. Heat Safety Education

Educate all employees about heat safety before they begin work in a hot environment. Provide educational materials in a language and literacy level that employees can understand. Heat safety education programs should include:

- The importance and process of acclimatization and how to follow the plan

- How to recognize the signs and symptoms of heat illness

- Clear procedures to follow when someone has symptoms of heat illness, including first aid and how to call for medical assistance

- What causes heat illness (e.g., temperature, humidity, sun/wind exposure, workloads)

- How to minimize risk from heat illness (e.g., hydration, rest cycles, monitoring for symptoms)

- How to use heat-protective PPE (e.g., sunscreen, hats, cooling vests)

- Effects of lifestyle factors on risk for heat illness (e.g., use of drugs and alcohol, obesity)

Encourage employees to download apps, such as the OSHA-NIOSH Heat Safety Tool App, that monitor local weather conditions and notify users of heat advisories. OSHA also has a Heat Illness Prevention Training Guide available in English and Spanish.

Managers should receive additional training on implementing the acclimatization plan, responding to weather advisories, and monitoring and encouraging hydration and rest breaks.

5. Acclimatization

Acclimatization is a physiological process that improves the body’s tolerance to heat by gradually increasing the duration of heat exposure. It can take anywhere from several days to two weeks to adjust. Some acclimatization factors to consider:

- Most heat-related fatalities occur in the first few days of exposure because the body isn’t acclimatized.

- Acclimatization can be lost in just a few days away from the hot environment.

- Non-physically fit employees may require more time to acclimatize.

- Training and education are critical for both managers and employees.

Benefits of acclimatization include:

- Increased sweating efficiency (greater sweat production, reduced electrolyte loss in sweat).

- Work is performed at a lower core temperature and heart rate.

- Increased blood flow to the skin to lose heat.

CDC/NIOSH recommends that employees new to hot environments work 20% of the usual workday and gradually increase their time by 20% every day after that. Employees returning to the hot environment after an absence should start at 50% of the usual workday and gradually increase their time by 10% every day after that. This general timeframe may need to be altered based on the individual’s risk profile.

6. Engineering Controls

Use engineering controls to reduce heat stress on employees, including:

- Reduce physical demands of the job by using powered devices for heavy tasks, such as forklifts.

- Use air conditioning, fans, or misters; however, ensure any moisture generated is not a safety risk.

- Provide tents, shades, or canopies.

7. Hydration Plan

Provide an adequate and accessible supply of cool, potable water with individual drinking cups or bottles. Managers should encourage and monitor employee hydration. Employees should drink 1 cup of water every 15-20 minutes (32 oz./1 liter of fluid per hour). During prolonged sweating over several hours, they should drink sports drinks with balanced electrolytes and eat regular light meals to replace salt lost in sweat.

Provide convenient access to adequate toilet facilities. This will ensure employees do not avoid drinking water to delay bathroom use during work.

8. Work/Rest Cycles and Reschedule Work

Managers should consider shifting work schedules to early or later in the day during extreme heat conditions. Employees should take regular rest breaks in a cool/shady area to allow the body to cool down. In general, employees should have mandatory 15-minute rest breaks every hour. Rest periods may need to be longer or more frequent during extreme heat conditions.

Shorten work periods and increase rest periods based on the following conditions:

- As temperature, humidity, and sunshine increase (WBGT).

- When there is little or no wind or airflow.

- If employees are wearing heavy protective clothing or equipment.

- If the workload is heavy or strenuous.

9. Use the Buddy System

Heat illness can make people confused and unaware they are experiencing symptoms. Assign work buddies to monitor each other for signs of heat illness and ensure they follow the hydration and work/rest cycle plan. If employees must work alone, conduct regular remote wellness checks with the employee.

10. PPE and Clothing for Heat Safety

PPE for the prevention of heat illness may include wide-brimmed hats, sunscreen, or cooling vests that circulate cool liquid or have ice packs. If safe, employees working in heat may also want to sprinkle water over their skin or clothing or keep a damp cloth on the back of the neck.

When the job does not require specialized clothing to protect against other hazards (e.g. flame-resistant and arc-rated clothing), encourage employees to choose clothes made from cotton or natural fibers rather than clothing made from synthetic material. Avoid dark-colored, heavier clothing and opt for light-colored, lightweight cotton clothing.