20-S-07

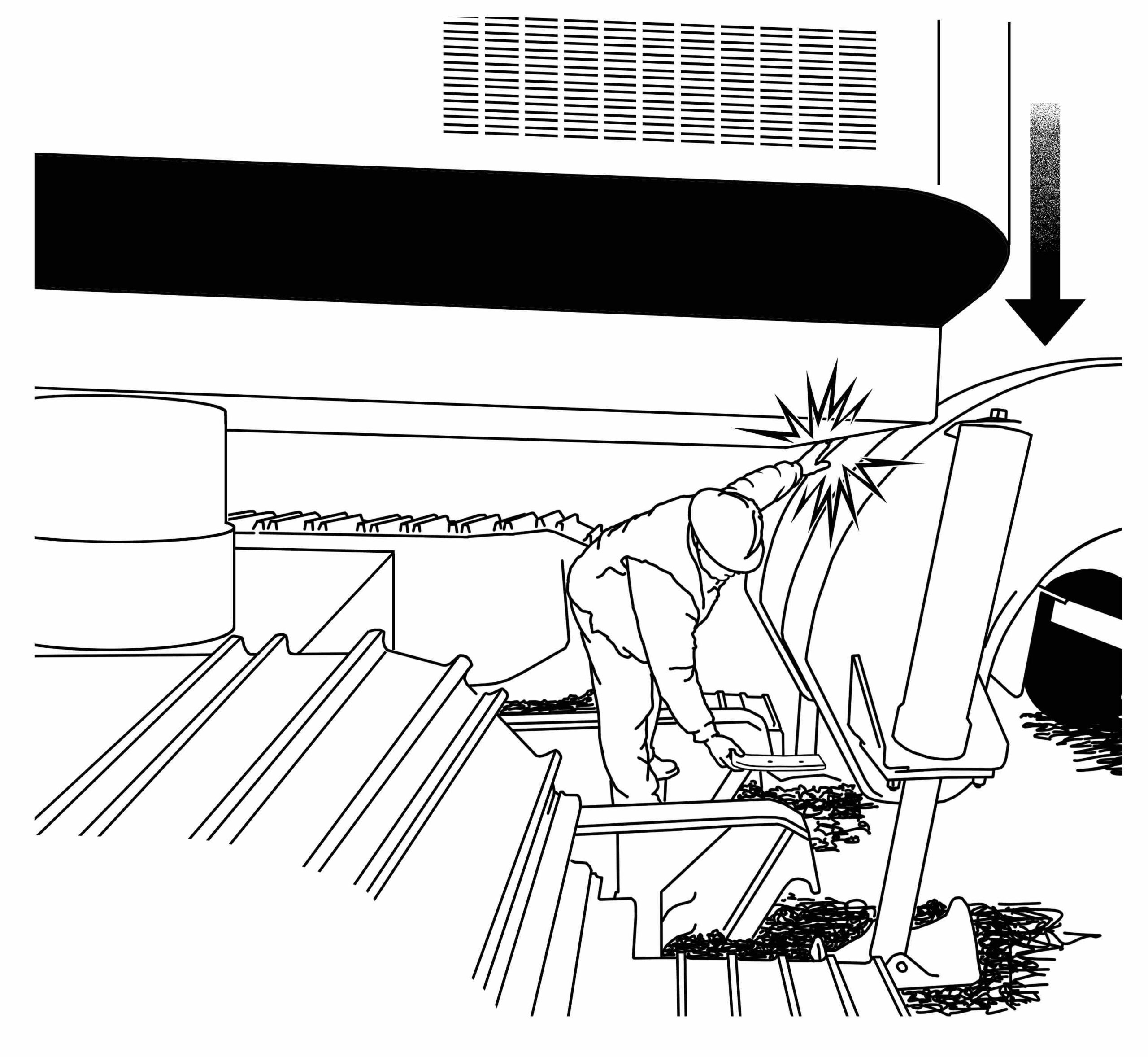

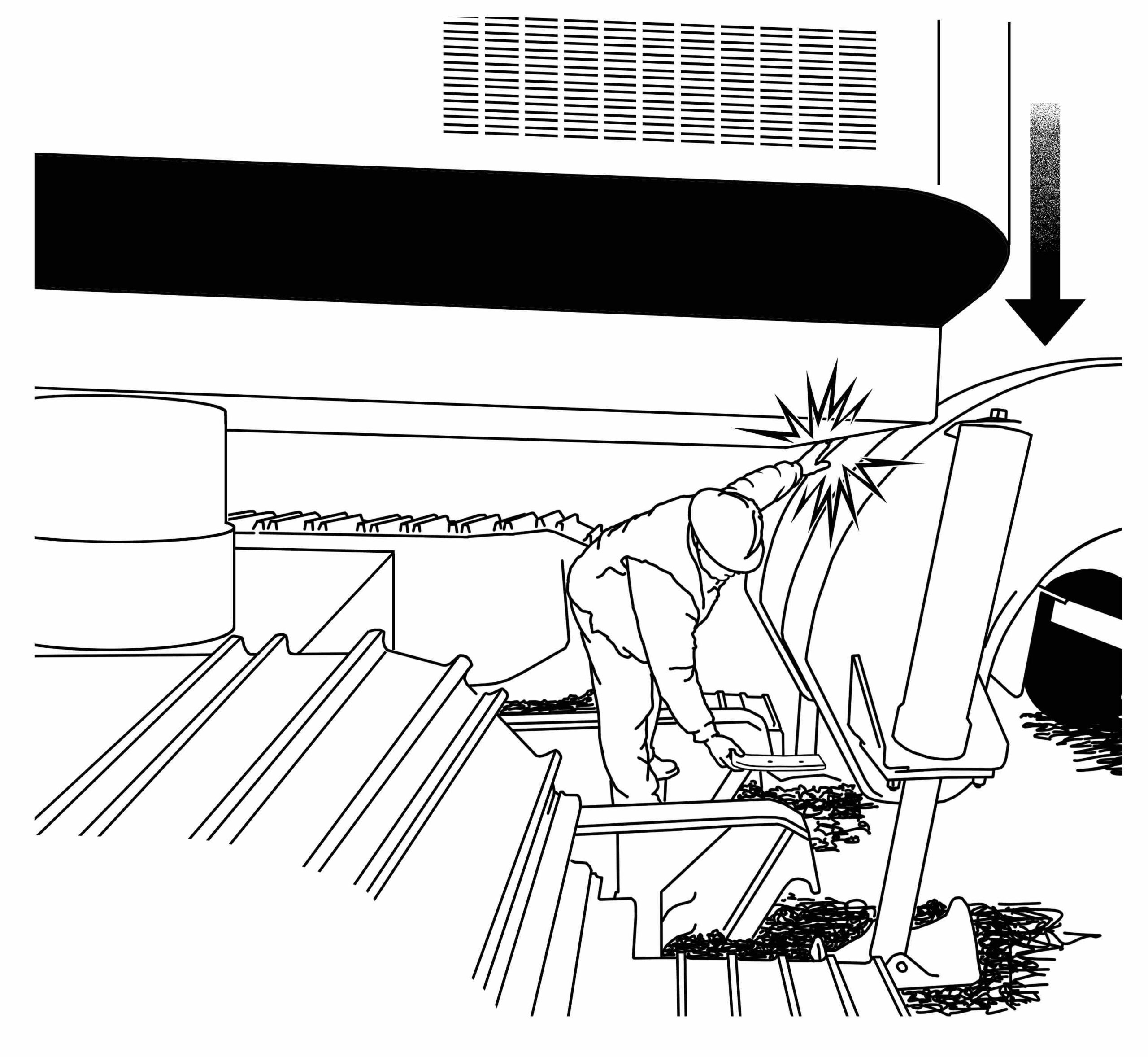

Lowboy Operator’s Fingers Amputated

Published

Content is restricted to FRA members only.

Sign In

Is Your Company A Member?

Get Access Now!

Reviewed By

Vickie Swanton, FRA Western Region Manager

Originally published by SHARP. Click here for their Logging Safety Brief.